| Period: | 01.06.2020 - 31.05.2021 |

|---|---|

| Partner: |

Physikalisch-chemisches Institut der Justus-Liebig-Universität Gießen

Associated partner: IoLiTec GmbH |

| Funder: |

Federal Ministry of Education and Research Funding code: 03SF0602A |

| Project managers: | Charan Mukundan, Martin Eckert, Willi Peters |

| Division: | Chemical Technology |

| Team: | Energy Storage and Conversion |

Motivation

The present project aims at pushing the Aluminum ion battery (AIB) up to a universal energy storage system (ESS). Since market for local and decentralized electricity storage units connected to renewable energy sources inexorably grows and huge demand cannot be satisfied alone by established technologies such as lead-acid, Ni-MH and Li-ion batteries (LIB), novel alternative concepts are urgently required. One limiting factor besides price of raw materials for LIB is related to their predicted resource shortage. 10 kg Li and 10 kg Co are needed to power one 85 kW Tesla S car. While identified Li and Co reserves amount to about 54 and 7 Mio. tons, respectively those of aluminum are estimated to reach 30 Mia. tons. The AIB is, by contrast to LIB, an emerging technology that relies on abundant, relatively cheap, non-toxic and non-flammable electrode and electrolyte compounds.

Function principle of AIB

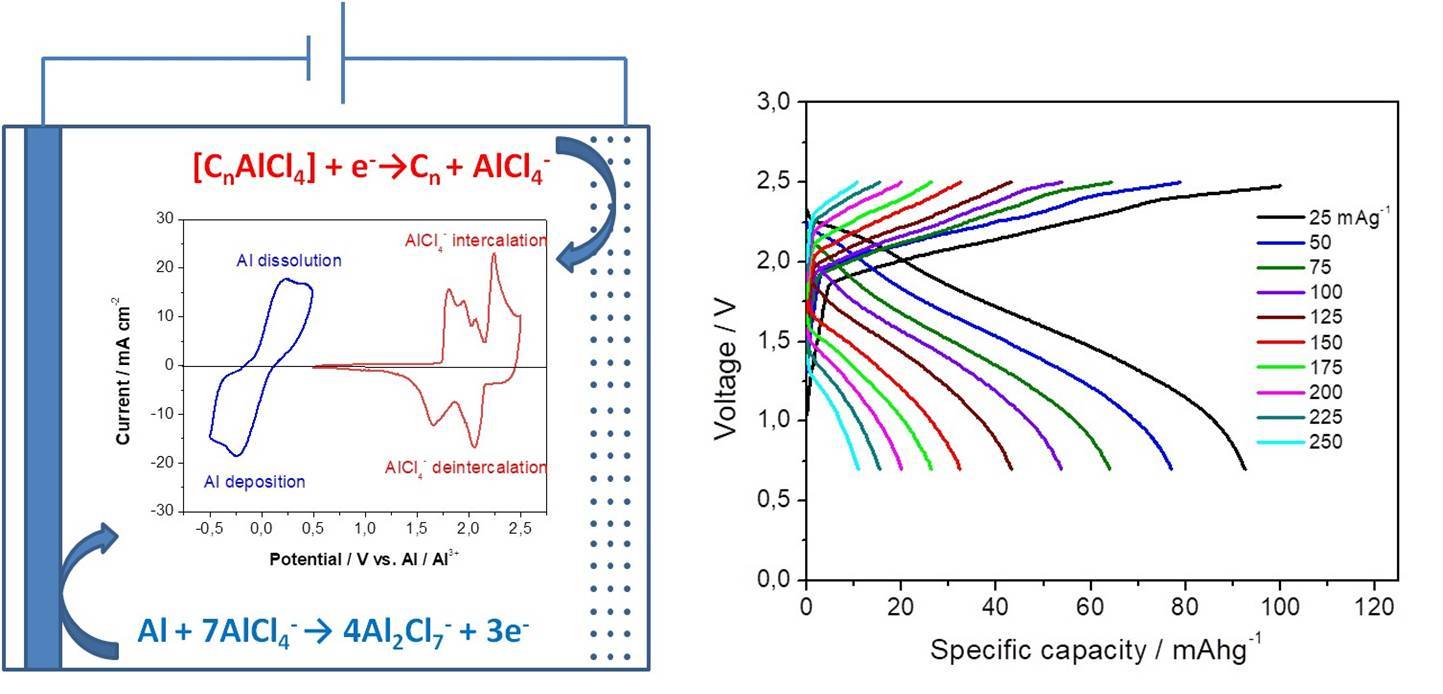

Figure 1: (Left) Cyclic voltammogramms of AIB half-cells in 1:1.5 EMiMCl:AlCl3- electrolyte by 10 mV/s with electrode reactions during discharging step. (Right) Charge/discharge behavior of AIB cell in function of current density from AliBatt project.

The function principle of an AIB is similar to that of a Li-metal cell. Most common cell chemistry is based on an aluminum foil as substrate for Al deposition/dissolution that acts as current collector as well, a water free aprotic chlorine-based ionic liquid (IL) as electrolyte and a graphitic carbon as positive electrode for Al intercalation/deintercalation. By contrast to LIB, in which small positive charged Li ions are exchanged, insertion of large negative charged AlCl4- ions is required for charge compensation of carbon matrix. In present concept, implementation of robust 26650 cylindrical cell design is planned that allows for a flexible modular storage unit up to 10 kWh and doesn’t pose any environmental risk if stored in cellars. Because of the low vapor pressure of the water-free IL electrolyte, self ignition, thermal runaway as well as explosion of AIB are excluded.

Strategy & challenges

When considering an operating period of 10 years for AIB energy storage system, further improvements regarding stabilization of graphite structure, inhibition of Al dendrite growth as well as corrosion resistance of materials exposed to highly aggressive electrolyte are needed.

Project aims & DFI tasks

ALISS project aims at developing an electrically rechargeable and scalable AIB storage system for countries in Europe, Africa (Sub-Saharan) and Indian subcontinent. Within the 1 year concept phase, DFI tasks will focus on (i) in-operando XRD analysis of graphitic carbon crystal structure prepared by AG Smarsly (ii), chemical and electrochemical tests of less corrosive IL electrolytes from IoliTec GmbH and (iii) elaboration of a technical and economical concept for 10 kWh AIB storage system that will be eventually developed during the 3 year project phase.

back

Part of the funding programme: Pilot innovation competition for breakthrough innovations related to a "world storage”

Dr.-Ing. Jean-François Drillet

Tel.: 069 / 75 64-476

E-Mail: drillet

Dipl.-Ing. Willi Peters

Tel.: 069 / 75 64-485

E-Mail: peters

M. Sc. Martin Eckert

Tel.: 069 / 75 64-447

E-Mail: eckert

M. Sc. Charan Mukundan

Tel.: 069 / 75 64-475

E-Mail: mukundan

Final report in German (PDF 2.9MB)

C. Mukundan, M. Eckert, J.-F. Drillet Batteries & Supercaps (2023), 6, e202300042