GA 1704/9-2

| Period: | 2015-09-01 to 2020-03-31 |

|---|---|

| Partners: | DLR, TUD |

| Funder: | German Research Foundation (DFG) |

| Project Manager: | Lukas Mengis, Dr. habil. Xabier Montero, Anke Silvia Ulrich |

| Research Group: | High Temperature Materials |

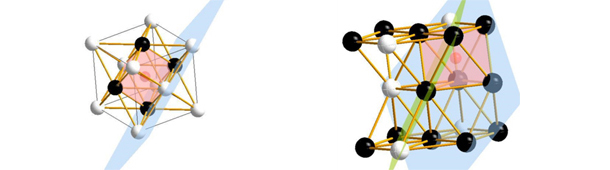

Intermetallic titanium aluminide (TiAl)-based alloys represent an important class of high temperature structural materials for applications such as turbine blades. Due to their low densities TiAl-based alloys offer the potential to substitute Ni-based superalloys and increase the efficiency of high temperature applications. Their operating temperature is currently limited to 750°C due to insufficient oxidation resistance and embrittlement. In previous projects a thermal barrier coating (TBC) concept was developed to protect the TiAl material from oxidation. However, the base material and its mechanical properties are affected by the coating deposition process. This project aims at understanding the impact of coating deposition on the subsurface zone and thus the mechanism of subsurface embrittlement. Based on this research the coating concept is optimized to maintain the mechanical properties for long term applications.

he coating manufacturing and mechanical analysis is done in cooperation between DECHEMA-Forschungsinstitut (DFI), Deutsches Zentrum für Luft- und Raumfahrt (DLR), and Technische Universität Dresden (TUD). The coating comprises a 7 wt.% yttrium-stabilized zirconia TBC layer, a thermally grown oxide (Al2O3), an Al-rich diffusion coating, and a fluorine treatment of the surface including a pre-oxidation step. The TBC layer, deposited at DLR, has a low thermal conductivity resulting in a steep temperature drop between the hot gas and the metal temperature of a turbine blade. The oxide grown on the diffusion coating is formed by selective oxidation of aluminium during exposure to air, providing an effective oxygen diffusion barrier and protecting the underlying metal from destructive oxidation. The selectivity of aluminium oxidation is enhanced by the halogen effect of fluorine treatment in conjunction with aluminium enrichment of the surface area. For the Al-rich diffusion coating two processes are used, the pack cementation process (DFI) and magnetron sputtering (DLR). The microstructure and chemical composition of the subsurface area are analysed after each deposition step. In addition the influence on the mechanical properties is investigated via 4-point bending, nanoindentation, tensile testing, and fatigue testing (TUD). Finally, the effect of each single layer and of the whole coating system on the oxidation behaviour of the TiAl alloys will be examined under isothermal and thermocyclic conditions (900°C) in air.

back

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) - GA 1704/9-2

PD Dr. Mathias Galetz

Tel.: +49 69 / 7564-397

E-mail: mathias.galetz

L. Mengis, C. Oskay, A. Donchev, M.C. Galetz, Surface and Coatings Technology 406 (2021), 126646

L. Mengis, A.S. Ulrich, P. Watermeyer, C.H. Liebscher, M.C. Galetz, Corrosion Science 178 (2021), 109085

A.S. Ulrich, N. Laska, A. Straubel, C. Leyens, R. Braun, M.C. Galetz, M. Schütze, Materials at High Temperatures 35 (2018), 204

Final Report (pdf, 1.6 MB, in German)