18947 N

| Period: | 2015-12-01 to 2018-05-31 |

|---|---|

| Funder: | Federal Ministry for Economics and Energy (BMWi, Germany) via AiF |

| Project Manager: | Dr. Alexander Donchev, Dr. Ali Solimani |

| Research Group: | High Temperature Materials |

Ti and Ni alloys are widely used structural materials due to their beneficial properties. Ti forms a passive rutile layer (TiO2) in oxidizing environments which is protective at ambient temperatures but gets deteriorated at higher temperatures (>600°C) and therefore loses its protective barrier effect. Hence, the oxygen inward diffusion becomes the rate-determining step and oxygen is enriched in the subsurface zone. This causes embrittlement which leads to failure of Ti components under cycling conditions (mechanical and thermal).

Technical Ni alloys usually form a chromia layer in oxidizing high temperature environments. This chromia layer has some disadvantages compared to alumina due to its evaporation in water vapor-containing atmospheres above 600°C and at temperatures above 900°C in dry air.

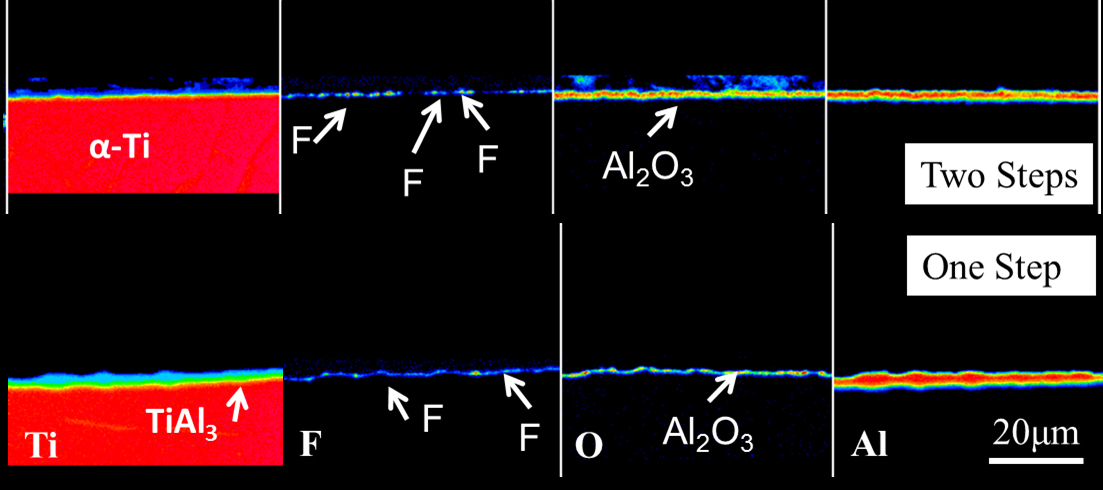

To overcome such problems the surfaces of Ti or Ni compounds have been modified. Single Al enrichment of the surface by coatings has been reported in the literature already, but these attempts were only slightly beneficial. An Al enrichment plus additional fluorine treatment proved to be much more beneficial which was shown already, but the two step treatment is more elaborate. A one step treatment will reduce the costs and save resources. The fluorine effect known from TiAl alloys with an Al content above 40 at.% will be transferred to Ti and Ni alloys with a much lower Al content. The formation of an Al2O3 scale is promoted by a defined amount of fluorine (fluorine effect), and this layer is protective against environmental attack even under thermocyclic conditions and in wet environments.

The parameters for the simultaneous Al enrichment and fluorination have to be evaluated and optimized. The subsequent investigations of the protective effect will prove the effectiveness of the treatment.

back

Das IGF-Vorhaben Nr. 18947 N der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Dr. Alexander Donchev

Tel.: +49 69 / 7564-386

E-mail: alexander.donchev

Final Report (pdf, 4.4 MB, in German)