M.-L. Bürckner, L. Mengis, E.M.H. White, M.C. Galetz

Materials and Corrosion 74 (2023), 79-90, DOI: 10.1002/maco.202213382

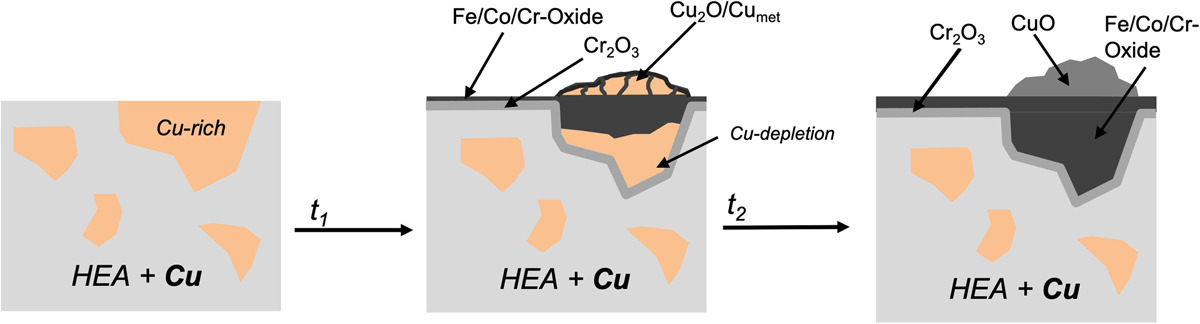

In this study, the oxidation behavior of FeCoCrNiMn (HEA + Mn) is compared to three modified HEAs manufactured by substituting Mn with Al, Cu, or Al + Cu. Oxidation tests were conducted between 600°C and 800°C for up to 500 h in synthetic air. Substitution of Mn leads to a significant improvement in the oxidation resistance for the three modified HEAs. For FeCoCrNiCu (HEA + Cu), a local attack of a Cu-rich phase was observed, leading to the formation of CuO blisters on the surface. The FeCoCrNiAl (HEA + Al) alloy was characterized by the formation of a thin Al2O3 surface layer for all temperatures. However, for the HEA + Al alloy the formation of AlN was observed after 300 h at 800°C, leading to a partial breakdown of the protective scale. FeCoCrNiCuAl (HEA + Cu + Al) by far showed the best oxidation resistance, characterized by the formation of a highly protective Al2O3 scale that effectively inhibited nitrogen penetration into the metal subsurface and local attack of the Cu-rich phase.