T. König, M.C. Galetz, B. Albert

Journal of the European Ceramic Society 41 (2021), 101-112, DOI: 10.1016/j.jeurceramsoc.2021.09.027

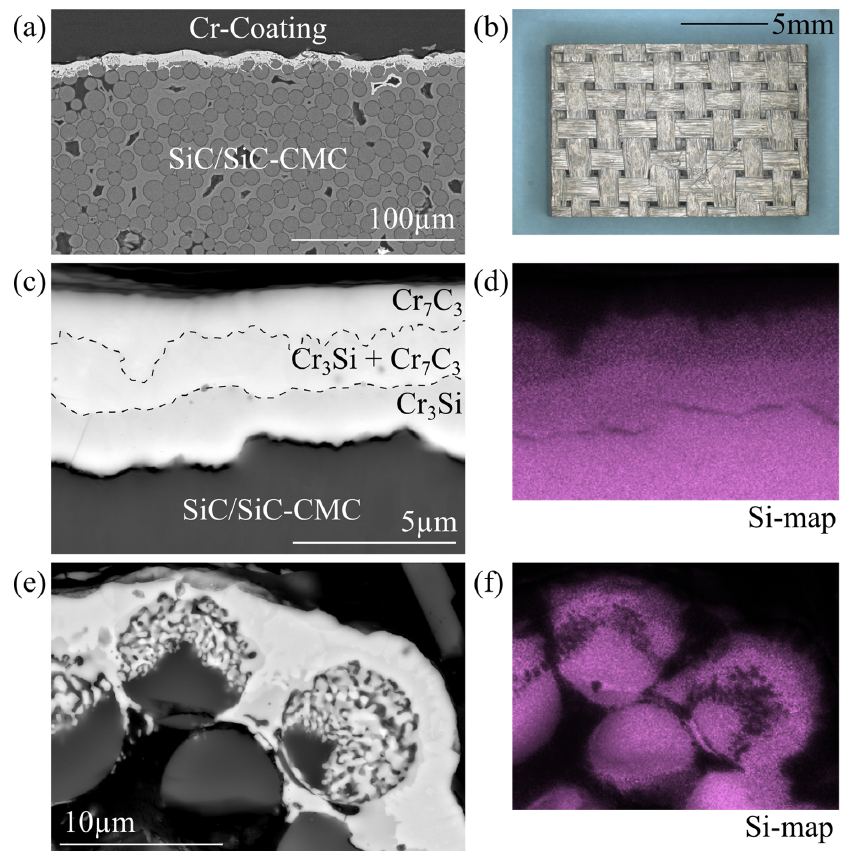

The potentials and limitations of a halide-activated pack cementation process on SiC/SiC Ceramic Matrix Composites for the development of bond coats as part of environmental barrier coating (EBCs) systems were investigated. Different pack compositions using chromium, aluminum and alloys of these elements were tested and the kinetics of coating formation were examined in addition to their microstructure. The results and their analogy to diffusion couples were discussed and it was shown that coating elements which form silicides and carbides are promising candidates for coatings deposited on SiC/SiC via pack cementation. Based on such considerations a two-step pack cementation was proposed, which used chromium, one of the suitable elements, in a first step, to finally achieve an alumina-forming coating. The oxidation resistance of the developed coating was tested via thermogravimetric analysis and compared to the uncoated material. The coating protected the fiber-matrix interface of the SiC/SiC Ceramic Matrix Composites from oxidation.