15087 N

| Period: | 01.02.2007 - 30.04.2009 |

|---|---|

| Partner: | Prof. Dr. Rolf Schuster KIT |

| Funder: | AiF |

| Project Manager: | R. Richter |

| Research Group: | Corrosion |

Aims

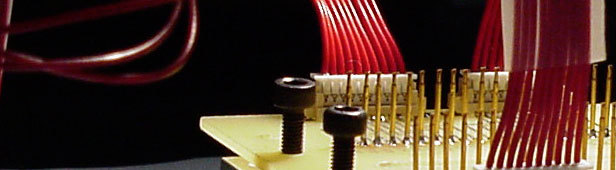

High-alloyed steels are important materials for modern microtechnology applications. With the miniaturization of components in the micrometer range, conventional machining technologies like milling, turning, spark erosion or grinding reach their limits. In this project, a new electrochemical micromachining method using short voltage pulses, presented in 2000 for the first time, will be applied for the machining/treatment of high-alloyed steels. On precious metals like copper and gold it could be shown that this method has the potential to structure metallic materials three-dimensionally with a lateral resolution smaller than 20 nm. However, micromachining of steels in aqueous electrolytes is limited by e.g. the passivation of stainless steels or the inhomogeneous microstructure of high-alloyed steels. To avoid these problems, organic, nonaqueous electrolytes will be used. Within this project, the electrochemical properties and the corrosion resistance of three groups of steels (low-alloyed steels, corrosion-resistant stainless steels and high-alloyed chromium-bearing steels) will be investigated first, using organic solvents added with conducting salt. On selected electrolyte-steel-combinations, micro machining tests will be conducted. The goal is to make nonaqueous, organic electrolytes or ionic liquids accessible for electrochemical machining to allow the treatment/structuring of high alloyed steels.

back

Das IGF-Vorhaben Nr. 15087 N der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Contact |

| Prof. Dr.-Ing. Wolfram Fürbeth |

| Telefon: +49 69 / 75 64-398 E-Mail: fuerbeth |

Publications |

| E.M. Moustafa, O. Mann, W. Fürbeth, R. Schuster ChemPhysChem 10 (2009) 3090-3096 |