18116 N

| Period: | 01.04.2014 - 30.09.2017 |

|---|---|

| Partner: | TU Braunschweig, Institut für Werkstoffe, Prof. Dr. J. Rösler |

| Funder: | AiF |

| Research Group: | Corrosion |

Introduction

The goal of the project IGF 18116 N is the tuning of gradiental mechanical and surface chemical properties on the alloy Ti13Nb13Zr. Today’s implants, as for example a hip implant, need different chemical and mechanical properties on one piece of implant. The upper part of a hip implant for example needs to be wear resistant because of contact with the femoral head. At the same time the lower part of the implant, the stem, requires a high degree of bone growth promotion (biocompatibility).

Project goals

At DECHEMA Forschungsinstitut (DFI) a partial anodizing process will be carried out. The upper part of the implant will be anodized by plasma electrolytic oxidation (PEO) to produce an abrasion and fretting corrosion resistant oxide layer. The lower part instead will be conventionally anodized in the presence of bone growth promoting substances. Via this way a biocompatible oxide layer will be produced. At the project partner TU Braunschweig the corresponding areas will be treated mechanically and by heat treatment in order to produce the required mechanical properties.

Results

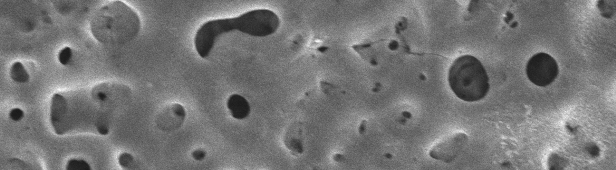

The influence of different electrical and chemical parameters on the characteristics of titanium surface layers obtained by plasma-electrolytic oxidation were examined. The focus of this research is on the Ti-13Nb-13Zr alloy, which was particularly developed as an implant material for medical use, unlike the Ti-6Al-4V alloy. Ti-13Nb-13Zr samples with four different microstructures (α+β; α“; α+α“; α+β+α“) were galvanostatically anodized at constant charge-carrier densities and current-densities reaching from 14 mA/cm² up to 817 mA/cm². Both a constant current mode and a unipolar pulsed mode with a duty-cycle of 50 % and frequencies of 1 Hz to 50 Hz were used. The surface layers were characterized by scanning electron microscope (SEM), electron dispersion X-ray spectroscopy (EDX), X-ray diffraction (XRD) and nanoindentation.

Several micrometer thick crystalline titanium oxide coatings with a porous structure could be generated in an undiluted and diluted electrolyte containing 1 M H2SO4 + 0.1 M H3PO4 and 0.1 M H2SO4 + 1 M H3PO4 respectively. The coatings consist of anatase and rutile, the phase composition of the coatings can be adjusted by the PEO current density. It can be shown that porosity can be reduced with increasing frequency.

The corrosion resistance of these layers was tested in a simulated body fluid (SBF) with the addition of 0.1 M H2O2 by open circuit potential measurements, potentiodynamic polarization and electrochemical impedance spectroscopy. Higher current densities during the PEO process formed thicker and denser coatings, which consequently resulted in lower corrosion currents. A pulsed process caused improved corrosion behaviour in the diluted electrolyte. This effect did not occur in the more concentrated electrolyte. The addition of zirconium oxide nano-particles into the electrolyte increased the surface hardness to an average value of 11.4 GPa, compared to that of an untreated sample (4.1 GPa) and a sample without particle addition (8.5 GPa).

The improvement of the biocompatibility of titanium implant surfaces by modification of its morphology and the application of hydroxyapatite (HAp) is an ongoing challenge for today’s implant technology. As a result, PEO was used to generate HAp layers on the Ti-13Nb-13Zr alloy in an electrolyte consisting of 0.1 M Ca(CH3COO)2·H2O + 0.05 M NaH2PO4·H2O. At a current density of 14 mA/cm² only anatase and rutile could be detected within the XRD-spectrum. HAp was formed in-situ at current densities of 139 mA/cm² and higher. The corrosion resistance of these apatite containing layers was analyzed again in SBF + 0.1 M H2O2. The higher corrosion potentials indicated that all HAp coated specimens offer a better protection than the untreated samples.

The specimens in their initial uncoated state show good corrosion resistance in artificial saliva + 1000 ppm NaF. The corrosion currents are higher, when both the alpha and the beta phase is present in one sample, due to the development of a local element.

back

Das IGF-Vorhaben Nr. 18116 N der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.