472ZBG

| Period: | 01.04.2013 - 15.08.2016 |

|---|---|

| Partner: | Fraunhofer-IKTS, Dresden |

| Funder: | AiF |

| Project Manager: | M.Sc. Dominik Tabatabai |

| Research Group: | Corrosion |

Project goals

Recently there is an increasing demand for magnesium alloys as low weight construction materials for the transport and automotice sectors. However, due to their high reactivity, these materials require particularly good corrosion protection. Plasma-electrolytic oxidation (PEO) was developed as a method for surface refinement of magnesium alloys. While this approach already leads to an improvement of the corrosion properties of magnesium alloys, a subsequent sealing of the protective coatings can even further enhance the corrosion protection significantly. However, a disadvantage of established organic sealing materials is their limited thermal and abrasive durability. Furthermore, PEO is an energy-intensive process.

The implementation of ceramic particles as a sealing material during anodizing is a promising alternative. Thus, the aim of this project is the development of a modified pulsed plasma anodizing process, combined with the application of chemical nanotechnology. By optimizing certain process parameters the energy consumption of the process is to be reduced. Furthermore, nanotechnology should help to optimize the properties of the plasma-electrolytic oxide coatings. This approach should lead to ceramic protective coatings with the following properties:

- anorganically sealed

- high corrosion resistance

- self-healing properties

The innovative character of this approach results from the combination of pulsed PEO with chemical nanotechnology. It should allow the creation of ceramic protective coatings on magnesium alloys with improved properties and lower requirements in terms of energy consumption. These coatings should offer good protection from corrosion and abrasion for magnesium alloys. A particularly innovative aspect lies in the introduction of self-healing properties for the preservation of the corrosion protective characteristics of the coatings, achieved by the release of corrosion inhibitive substances.

Results

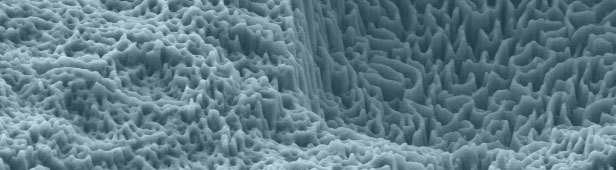

It was shown that a reduction of the KOH content of the anodizing bath down to 5 g/L is beneficial to the morphology of the anodic oxide coating. Instead of an open pore structure, the pores appear fused for the most part. The positive influence of this change on the corrosion properties can be shown via potentiodynamic polarization.

Through dispersing SiO2 nanoparticles in the anodizing bath these can be incorporated into the anodic oxide coating. Via electron microscope imaging of the cross section of the coating the incorporation of the nanoparticles into cavities of the anodic oxide coating can be verified.

Zeolite nanoparticles can be doped with Ce3+ ions through a typical cation exchange reaction. The incorporation of accordingly modified nanoparticles into the anodic oxide coating leads to improved corrosion properties, as can be shown via potentiodynamic polarization.

Microporous SiO2 nanoparticles can also be doped with Ce3+ after modifying their surface with an amine functionality via a reaction with a corresponding silanyl compound. Nanoparticles which were thus modified and doped with Ce3+ ions release those ions selectively at a pH value below 5.

Future Work

Future work will primarily aim at improving the loading of microporous nanoparticles with corrosion inhibiting Ce3+. This should be achieved through optimizing the chemical modification of the nanoparticle surface. The optimized particles are to be incorporated into anodic oxide coatings, and their corrosion inhibitive properties are to be assessed via electrochemical methods and exposure tests.

back

Das IGF-Vorhaben Nr. 472ZBG der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.