IGF 21671 N

| Period: | 01.06.2021 - 31.12.2023 |

|---|---|

| Partner: | Technical University Braunschweig, Institute for Materials Science |

| Funder: | AiF |

| Project Manager: | M.Eng. Julian Fritzen |

| Team: | Electrolytic Corrosion |

Description of the problem

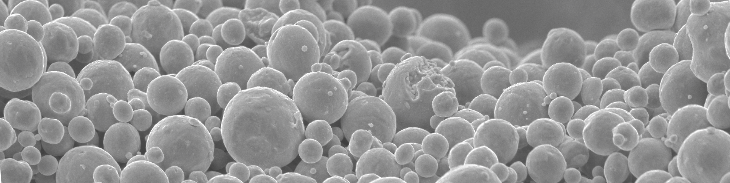

Titanium and its alloys play an increasingly important role in aerospace, automotive or medical applications. Particularly the manufacturing of small and complex components or series, the specific alloy and the manufacturing method must be chosen carefully. Additive manufacturing is a suitable and contemporary method for this task. Applying selective laser melting (SLM) process, manufacturing of complex structures layer by layer is possible, thus the loss of material is very low and is limited to support structures required for printing and powder particles sticking to the samples.

For the use of dental implants made of titanium materials, the biocompatibility, corrosion resistance and mechanical load capacity are of particular interest.

Approach

Within the frame of this project, new titanium alloys without the use of (neuro)toxic elements such as aluminum and vanadium are being developed. Therefore, only essential elements already present in the human body or that are biocompatible will be used. Bioactive hydroxyapatite layers are going to be applied (using plasma electrolytic oxidation, PEO) to further enhance osseointegration of the implants. Among other things, these layers also improve the corrosion resistance.

The titanium alloys developed by the cooperation partner at Technical University Braunschweig are tested for corrosive properties to determine the dependency of the component properties on the SLM parameters.

For this purpose, potentiodynamic polarization, electrochemical impedance spectroscopy and tribometric tests are carried out in various electrolytes.

Goal of the project

The aim of the IGF research project 21671 N is to develop additively manufacturable, biocompatible titanium alloys, which have reproducibly good mechanical properties, comparable to those of conventionally produced standard titanium alloys. The long-term goal of the project is the patient-specific additive manufacturing of medical technology products based on e.g. X-ray imaging or an MRI image. CAD files can be created from this data, which are used to program the SLM system. In this way, the exact structure of an implant could be produced, individually tailored to the patient, and osseointegration, and thus the chances of recovery, could be improved. In addition, the production of tailor-made implants can also be quickly realized for small and medium-sized companies with this technology.

back

Das IGF-Vorhaben Nr. IGF 21671 der Forschungsvereinigung DECHEMA e.V. wird über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.