DFG-SPP1640 A2

| Period: | 01.01.2013 - 30.06.2019 |

|---|---|

| Partner: | Prof. Dr.-Ing. G. Wagner, M. Thomä; TU Chemnitz, Lehrstuhl Verbundwerkstoffe

Dr.-Ing. B. Wolter, Dr.-Ing. B. Straß; Fh IZFP, Saarbrücken |

| Funder: | DFG |

| Project Manager: | Dr. Sigrid Benfer |

| Research Group: | Corrosion |

Aim of the Project

Only with hybrid construction is it possible to combine the advantages of dissimilar materials. Force-fitted or form-closed joints can be realized in an easy manner, but the strength of welded joints can rarely be achieved. However, fusion welding of dissimilar materials is often impossible as a result of the different melting ranges. Moreover, in many cases undesirable mixed phases occur in the weld area, whereby the attainable strength of the joints will be reduced.

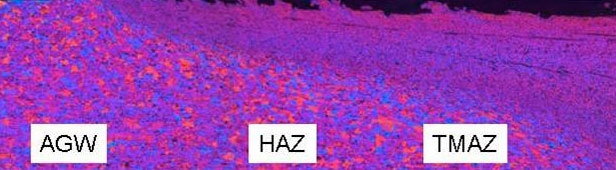

The aim of the research project is to use friction stir welding (FSW) to join material groups that are well established in industrial applications, but that cannot be joined by fusion welding. These are the light weight materials aluminum and magnesium as well as aluminum and steel. FSW enables a joining by plastic deformation. To eliminate strength reducing effects by occurring brittle phases and to improve the stirring in the joining area power ultrasound is additionally transferred into the welded area (USE-FSW). An estimation of the quality of the produced welds will be carried out by monotonic and cyclic as well as non-destructive investigations. To determine the complex problems of corrosion of the hybrid material joints, detailed examination of the corrosion behavior, especially of the welding area, are made.

Results

The USE-FSW process has been successfully applied to Al/Mg-hybrid joints out of EN AC-48000 und AZ80 alloy. The additional ultrasound showed a positive effect on the mechanical properties (tensile strength). The great potential difference between the Mg-alloy and the nugget phase leads to the formation of a galvanic element in this region and, therefore, to accelerated corrosion of the magnesium at simultaneous electrolyte contact (s. S. Benfer et al., Surface and Interface Analysis, 2016).

After that the process was applied to the manufacturing of joints made out of an Al wrought alloy (EN AW-6061) and cold rolled DC04 steel. The corrosion properties of these joints have been characterized in analogy to the Al/Mg ones by Scanning Kelvin Probe (SKP) measurements first. The Volta potential difference between the Al alloy and the steel is about 0.9 V, with the Al alloy showing the more negative values. This is a similar difference to that measured between AZ80 Mg alloy and AC-48000 Al alloy where the Al alloy has shown the more positive values. From that result one would expect that the EN AW-6061 Al alloy will show stronger corrosion in corrosive media than the steel particularly if both phases are in simultaneous contact to an electrolyte. The measurements in air are not directly transferable to those in a liquid electrolyte, as the open circuit potential (OCP) measurements in 0.5 molar NaCl solution show. After the immersion time of 60 minutes the OCP difference between the materials is only about 50 mV or less, with the steel exhibiting the more negative values. Therefore, the risk of enhanced corrosion caused by a galvanic element is much less pronounced than in the case of the Al/Mg-hybrid joints (s. M. Thomä et al., Journal of Materials Science & Technology, 2018).

With EN AW-6061/C45- and EN AC-48000/AZ91-joints other alloy combinations in the systems Al/steel- and Al/Mg have been realized. The results of the characterization of these joints have been submitted for publication. (M. Thomä, G. Wagner, B. Straß, B. Wolter, S. Benfer, W. Fürbeth, New developments in the field of ultrasound enhanced friction stir welding of dissimilar materials; accepted paper for the 12th International Symposium on Friction Stir Welding, 2018). In case of the EN AC-48000/AZ91- joints the influence of ultrasound parameters like power and side of introduction on the joint properties have been investigated, too. (A. Gester, M. Thomä, G. Wagner, B. Straß, B. Wolter, S. Benfer, W. Fürbeth, Hybrid Joints of die-casted Aluminum/Magnesium by Ultrasound Enhanced Friction Stir Welding (USE-FSW); accepted paper for Welding in the World, 2018).

back

Funded by the Deutsche Forschungsgemeinschaft (DFG) within the Priority Programme "Joining by plastic deformation" (SPP1640).

Dr. Sigrid Benfer

Tel.: 069 / 75 64-382

E-Mail: benfer

B. Strass, G. Wagner, C. Conrad, B. Wolter, S. Benfer and W. Fürbeth

Advanced Materials Research 966-967 (2014) 521-535

S. Benfer, B. Straß, G. Wagner, W. Fürbeth

Surface and Interface Analysis 48 (2016) 843-852

S. Benfer, W. Fürbeth, M. Thomä, G. Wagner, B. Straß, B. Wolter

Marco Thomä, Guntram Wagner, Benjamin Straß, Christian Conrad, Bernd Wolter, Sigrid Benfer, Wolfram Fürbeth

Chapter Friction Stir Welding and Processing IX, Part of the series The Minerals, Metals & Materials Series pp 179-194

M. Thomä, G. Wagner, B. Straß, C. Conrad, B. Wolter, S. Benfer, W. Fürbeth

Journal of Materials Science & Technology 34 (2018) 163-172